I picked up a couple of old these old SR seatposts with the closed tops. They work well because the top provides a good bolt seat and after drilling it out to the correct size, the bolt fits snugly in place. A regular plain old seatpost could be used as well with washers or a little machined cap to hold the bolt in the center. Seatposts with a built in clamp will work but you must be choosy about finding one with enough area and material for an added bolt hole. I made a previous quill seatpost using this same Kalloy model pictures in this Yellow Jersey article on this same subject.

Yellow Jersey Quill Seatpost Article

I also picked up some old 1 1/8" stem quills. Their o.d. is larger than 27.2 so they were perfect for milling down to size.

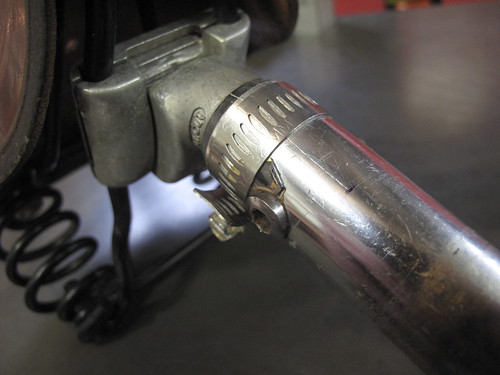

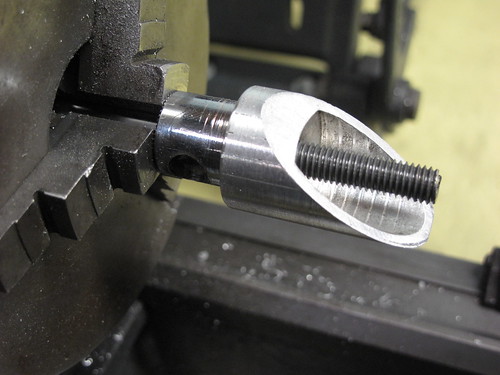

To hold the wedge simple screw it onto the stem bolt and vice it up in the chuck. Adding a spacer provides some room for the cutter to pass.

Then you'll need to cut the post at a 35° angle. Or whatever angle your wedge is. I cut mine at a 45° angle mistakenly and then cut it to 35°. That is why a little too much bolt is protruding. It will work but it is even shorter now. I recommend trying to find stem bolts that are 9 inches or longer, if such things exist.

A little more searching for longer stem bolts, and I will make some more.